The "Turbine Project"

My buddy Eric gave me this Jo-Han '63 Chrysler Turbine model a couple of years ago for my birthday. I have to put it together now. It'd be wrong not to make it. He had this for a few years,...since '89, I think, and he knew he couldn't do it, (it over whelmed him) so he gave it to me.

I'll be putting it together over the next few months..a little here...a little there, and I'll document it for the model or car fans. I'll try to show every detail and process. I'm sure I'll put other quicker models together in between here..and there...but this one is a long range project.

Jo-Han models are incredibly detailed. The seats alone can fold down and are made up of 5 pieces each seat!! The doors open, as does the hood and trunk. The steering works and..get this..the suspension is supposed to work with real tiny styrene springs!! This is the most detail kit I've ever worked on...and over the many years of building kits (since the 3rd grade) I've built hundreds...literally.

Here's some pics of a real Chrysler Turbine...

Pretty cool.

The engine is not a standard engine...it's a gas turbine engine. Using a high speed air intake, one spark plug, and fuel injection, the engine super heats the air and fuel, driving the turbines

even faster. That's transmitted to the transmission, then to the rear wheels.

That's a simple explanation.

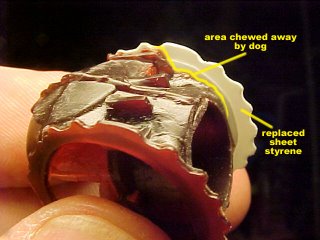

When I got the kit, Eric said his puppy (a few years ago) chewed into the box. After opening it and looking at the contents,

I found out that the little fart chewed part of the rear right door interior panel...and a thin plating on the main turbine housing. Everything else seemed ok.

I started with the engine, as you usually do with car models. I took careful note of the damage, compared it to a real engine (see pic), then went to repairing it.

I traced the other housing plating onto a a sheet of styrene & cut it out with manicure scissors. I then added a secondary sheet to match the thickness of the other side, then sanded the exact gaps and points with a pin file.

I glued the plates to the side of the housing and filled any gaps with squadron putty.

I sanded and fine tuned all irregularities, primed it with flat black..then a gloss.

The kit came with a lot of chrome parts for the engine, and since I don't think that models should have that glossy looking chrome on the engines...and after checking my reference pics again...I hit the chrome parts with Testors dull coat to bring it down to a machined aluminum look.

I glued the chrome parts (burner cover, exhaust convergers, transmission case, etc.) to the main housing with Testors Styrene glue...the watery stuff.

I noticed on real cars, the nozzle actuator...the chrome thing on top...had a red coil cover that wasn't made for the kit. So I made one with coiled wire and will connect it to the proper point once I drop it in the car

. There are some other actuator rods and stuff that I'll fabricate, but for now...this is good.

2 Comments:

Man, that's excellent detail.

What camera are you shooting those close-up with?

(Like you shot your cool "Fuzz" model with)

The early close ups...the mending of the plates...was the clunky Mavica. The last shot of the underside of the engine was with the Nikon Coolpix 5400. The Mavica is good for controlled light pics, but you can't make light and shade too complicated or it looks just like an old video camera.

Post a Comment

<< Home