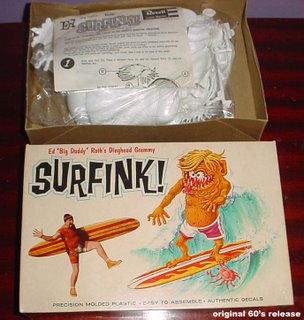

Surfink (post #150)

(...or, The Longest Post Ever to Grace this Blog or, This Was Supposed to Be a Quicky Project)

A lot of people have been e-mailing me and asking me where I've been, cause I haven't posted in a couple of weeks. I've been trying to finish this giant post. The production of this post, has been more demanding than the actual subject of the post. I kid you not.

ok....

Of all the models that I've built for myself (and sold) or have built for others on

commission, I've never been able to build Ed Roth's classic Surfink.

A few years ago I bought one finally, but had to sell it before putting it together. I got another one just recently off of Ebay and jumped on building it before I weakened and put it in storage. One of the things I didn't like about the kit is that the surf is just white plastic. I felt it should be clear, like water...so the first thing I set out to do on this kit was to make the wave clear. I'd worked with losts of different resins, but I knew the good water clear resins were professional grade and ran pretty high on cost ($60 per qrt). Castin' Craft's Clear Resin ($20) has been around for a while and I've noted on several disscussion boards that many people have had the same problem I've had in the past with this stuff. It sets up fine...but the surface remains tacky for days....months. If you touch it, you leave indented fingerprints. This dulls the glossy look and deminishes the clearity. I decided to just make a mold of the wave for now, and figure it out later.

I took the original wave and glued it together with styrene glue and puttied the seams with Magic Sculp.

I decided to add more wave like shapes to the design with more Magic Sculp.

I closed off the top of the wave with a peice of sheet styrene cut and fitted to the opening.

I added more putty to help blend it in and close up any gaps, as this would let the silicone seep in when it's cast. I planned to make a "case mold" of the wave due to it's odd shape. A case mold is a two, three, or how many ever, part mold of a shape that's hard to cast with a conventionial two part, or "sandwich" mold.

I took my molding clay, Klean Klay...which has no sulfer content (a no no with silicones) and rolled out peices 1/4" thick.

I then layed this "blanket" over the shape and blended the clay where needed. The idea is to make a blanket thickness at least 1/4" all over your original. This is the shape and thickness your silicone will be later after a couple of steps. This step assures you that the silicone mold itself is thick enough uniformally.

After it's fairly uniform all over, I add keys on the section that I'll make the front and the section I'll make the back. These keys help the outer plaster jacket (that's about to go on) to stay in registration.

I then form a clay wall to help form the back half of the outer plaster mold. Once the back half of the plaster mold is brushed on, formed and then dry, I remove the clay wall leaving the front half.

I then coat the facing wall of the plaster with vaseline and lay on the other half of the plaster mold.

After that's dry, I carefully pry the back half away and pry away half the clay blanket as well, exposing the actual model. I "re tool" the exposed clay and form "registration keys" on the clay's surface.

These keys will be used to register the silicone mold edges to one another. How? Read on. I take the back plaster section and drill a large pour spout to allow the silicone to flow into it.

As you can see, the first spout was too low....the key is to get your silicone poured as high onto the actual model as possible for an even coating. I redrilled another spout and plugged the old one with clay. Next, I secured the bottom of the model with clay, as to not allow silicone to leak under it, then secured the back half of the plaster mold to the front with a large rubber band (the type use in ceramic molds). What we have is a space in just the back half for the silicone to fill. I mix up some silicone, (amount based on the clay removed from that half) and poured it into the spout. To make sure the silicone reached every area, I drilled 1/8" holes to allow air to escape. As the silicone filled up and leaked out of those areas, I plugged them with clay. Once the silicone had filled the cavity, I let it sit for a few hours.

Later, I opened the front half of the plaster mold, carefully removing the clay blanket from the front, and exposed the back half of the cured silicone mold inside the plaster jacket. I greased the facing wall of the silicone mold with Vaseline.

This keeps the two halves of the silicone molds from bonding and allows them to be opened easily. The silicone back half holds the model in registration...so, to pour the front half, I closed the front, secured it with my rubber band again, and turned the mold over.

This way, I can pour the front half of the silicone mold from the bottom without drilling a hole in the top...like filling up a cup. After a few hours, that's set and I remove the two halves leaving a complete two piece silicone mold, outer plaster case, and model.

Simple, huh?

I noticed that by pouring the second half from the bottom, I got some bubbles on the surface of the waves. There was no where for the air to go. No problem, once I cast the resin, I'll dremel the bubbles and make smaller waves from them. I did a test pour of the clear resin first, to see how it would take to the mold...how much color tint to use, etc. It looked promising. It cured and came out of the mold fairly quickly. This test piece is good for testing other effects, i.e.-dremmel reactions, clear coating of differnt chemical makes, etc. I then poured the real deal. I measured out what I thought would fill the mold, gave the resin a squirt of the activator/catalyst and stirred it thoroughly.

I researched the resin/catalyst ratio on line and in Castin' Craft's instructions. They spoke of drops per ounce. I've worked with resins a long time and I've always just eye balled the catalyst amount and literally measured it in squirts. The "drop" method has yeilded very slow results in the hardening of this brand of resin. Castin' Craft sells a "surface hardener" but I didn't feel like waiting to order it on line. I poured the resin into the mold, almost to the surface, then with the leftovers in the cup, I mixed in half a drop of blue green resin tint...then poured that into the mold as a final layer. I mixed the tinted with the clear to break it up, and knowing that the real ocean looks darker as it gets deeper, I kept the tops of the waves crystal clear and the base a richer blue green. I let the resin sit up and by that evening it was totally hard. As usual, the surface was still tacky, so I decided to cure out the peice with a heat gun and "force cure" the resin. I hit the base surface for about 10 minutes with the heat gun and let it cool off.

I took it out of the mold and waved the heat gun slowly over the rest for about 10-15 minutes until it was'nt tacky to the touch. I suppose you can amp up your catalyst even more for a quicker cure, but you risk the clearity going darker and even cracking of the resin. I let that sit while I tackeld Surfink himself.

He's pretty straight forward like most of the fink models, being made up a front half and a back half . While I was checking the fitting, a fly landed on Surfink's mouth.

I took this as a sign from Ed that it was all cool. I then started taking seams off of pieces and used a trick that works for organic shaped models. I scraped the seams off of the tongue

and hands

with an X-Acto knife and then brushed a liberal amount of the Testor's styrene glue over them to melt and smooth them out.

This usually works and needs no sanding. I did a test fit of all the parts to see how the hand and arm were going to work. I never liked the way the right arm reached in front of the character.

I've always felt it should be more out to the side to give the impression that he's balancing himself. After I got that in my head, I glued the right hand to the right arm. The hand position wasn't right either, so I snapped that off and glued the hand to the wrist in a more natural position,

then blended it all with putty.

To facilitate the proper angle for the arm, I cut a 45 degree section from the shoulder

and flattened the opening with putty.

While that cured, I put the body together with Testor's styrene glue, holding the halves together with rubber bands. I went after the slightly off set seams with white squadron putty,

which is perfect for the finer seams, and sanded them smooth. I glued the arm onto the shoulder with Krazy Glue Gel and began to putty the connetction and larger seams with Magic Sculp.

I resculpted the shoulder..

..filled out the ankles, etc. I let the putty set up over night and came back to sand and blend out everything.

Another thing I didn't like about the original model was that funky hair. I liked the front...don't get me wrong. It looks just like Roth's drawing...it's the back that get's me. There are two hair lines in the back...

..one on the scalp and the one of the actual hair peice. If you lay the hair where it's supposed to be, it's just...weird lookin'. So...I cut the back half at a strategic location, Krazy Glued it in place,

then puttied on a new, more compliant hair doo.

I blended it out to the actual sculpt and added flying strands (like the front). I primed this and the surfboard with a white primer.

After the board was dried, I did a wet sand on the top and bottom and then taped the stripes off. I sprayed on the primary coat of bright yellow with Design Master floral paints...

(the same brand used in this post..and this post).

After peeling the tape away, I re-taped for the center black stripe. Once the black stripe was dried, I sprayed the whole thing with a layer of Testor's dull coat, just in case I slip while painting the red flames. If I have a slip, the yellow, white and black will be sealed and it's as easy as wiping with a wet Q-Tip to remove any unwanted red paint. The sealer keeps the acrylics from bonding and it's easy to "erase". I hand layed the flames with two layers of acrylic, giving the front end a brighter orange/red and the back a darker brick red. After that, I gave the board 5-6 coats of Plaid's Clear Gloss,

...letting each layer dry first before adding the next. I wanted a deep gloss as if the board's been painted like a car AND wet.

I go back to the wave and dremel out the bubble with a rounded bur bit.

I shape it to a lesser wave shape. I then coat this and any other surface defect or sanded seam with Krylon's Triple Thick Crystal Clear Glaze.

An extra layer of clear makes any acrylic, lexan, or lucite scratch or scar go invisible again. (as a side note: If you have a windsheild or any clear styrene that's scratched or fogged by glue, ...you can brush on a coat of Future floor wax and it will go totally clear again. With the clear resin, this is the same principal.) The triple thick glaze also kicks the shine up if there are any fingerprints.

I added the white foam with a light dabbling of acrylic paint and sealed it with Krylon's Triple Thick Glaze.

I then glued the board to the wave with 5 minute epoxy and waited for it to dry, then glued the wave to the wooden base (after painting a green shadow texture with acrylic)

with 5 minute epoxy.

Back to the Grimmy himself...once the "baggies" were taped off,

I painted a base coat of light brick red on all the fleshy areas...I even went over the eyes. I then drybrushed a slightly lighter shade of flesh over the whole area.

I say slightly lighter, because if it's too much lighter, it creates a contrasty effect and we want to work our way to highlights gradually. If the next layer of drybrush is too stark, you can make up a batch of that same shade as a wash...like a water color... and brush it all over the area. This will bring the shadows up a little lighter, but not really effect the lightest shade. On my last layer, I went with a wash

and added a smidge more pigment to lighten his belly chest and some back, to simulate a slight "farmer tan"...as if he had on a t-shirt for most of the summer. I left the inside of the mouth dark, but ran a wash of red over the lips and tongue. I drybrushed that with a lighter rose shade. The teeth got a drybrush layer of ochre, then another layer of lighter ochre, then on the tips, a brushing of white.

The eyes got a drybrushing of ochre/off white, then a final layer of white. I capped them with spots of pure black for the pupils. The veins were red washes with a fine tip brush, following the sculpted veins. The hair was drybrushed with a golden brown then a lighter brushing of golden yellow.

Here, again, the contrast was evident and I did another wash of the golden yellow to blend the shadows more. Very carefully, on the grimmy's shoulder,

I lined in Roth's logo as an old school dark green tattoo using a fine brush. I peeled the tape off and painted the shorts according to the original box art...a patch work of lavender panels.

I sprayed the whole thing with Testor's Dull Cote and glossed the mouth, tongue, and eyes with Krylon Triple Thick Glaze. I also spattered the area nearest the board with the Plaid Gloss to simulate a splashed wet look, by holding the spray nozzle half way down and allowing it to sputter. I glued him to the board using my trusty 5 minute epoxy, then turned to the small crab.

I primed him with white, painted him with pinks, and washed it with a darker red in places. I attached him to Surfink's toe with 5 minute epoxy and propped him up until it set.

Finished.

After years of planning and wanting to make the most of my first and only attempt at Surfink, I came to this final effect. I'm pretty happy with it and I'm glad I went all the way with the wave effect. If you'd like a clear wave for your Surfink kit, email me and we'll work something out.

Here's some shots of Surfink enjoying himself off the coast of Miami...

and off of Zuma Beach.

13 Comments:

I used to build toys when I was a pansy in my youth, then I joined the Navy where they made a man out of me during the day... and a woman at night.

Paaa Haaaa...that picture rocks!!

pretty foecking incredible, joe. your brain will make a fine trophy for my minions to admire and nibble upon.

Joe, your F'n AWESOME!!!!! =]

Paaa..Haaaa..THAT picture rocks, Steve!

Joe, you are a god among model builders.

That's one sweet fink!

Impressive. I have never had the patience to really make a model look good. I need projects where I can bulldoze my way from point A to point B without all that pesky waiting ("drying and curing? won't it do that when it's finished"). You have talent. The only thing my Dremel does is make holes. Sanding bit? Holes. Polishing bit? Hole. Grinding bit? Big hole.

Jeez man, that's really dynamite.

wow. that's a phantastic job!

I wish I had your patience.

I'd probably draw and sculpt more, and listen to music less.

It was worth seeing Secret Squirrel every day for a week, I tell you what. Great job!

AMAZING!! I envy anyone who can make model kits look as good as you do! No patience for it myself.

A solid clear resin base? How much does it weight?

-danno!

Post a Comment

<< Home